Sherman BARV

Commentaires

44 2 July 2024, 20:50

I think you win this weeks prize for most heavy duty modelling tool. 😄

Looks a very interesting conversion.

5 July 2024, 06:33

> I think you win this weeks prize for most heavy duty modelling tool. 😄

Probably, yeah 🙂 It's a metalworking lathe, so a bit overkill for just turning down the seam on those wheels, but I didn't feel like aching fingers from scraping them down with a knife — I get those even when I hold them in a modelling vice, never mind just between my fingers.

> that kind of set up can tool a real bogie!!

Having seen a disassembled Sherman bogie up close, I must say I think this one is a size too small for that 😉

5 July 2024, 08:53

@Mr D: that's not the welds yet, it's just the filler needed to plug the gaps 🙁 I'm still debating how to add all the weld seams.

@Ben M: An M2 screw, about 2 cm long, through the hole in the wheel, with a nut to tighten it. It needs to be fairly tight else chances are the wheel will stop as soon as the chisel hits it. On Asuka two-piece wheels, you need to do this before assembling the parts, because the hole on the piece to be glued in is smaller than on the part that has the tyre moulded on it.

9 July 2024, 08:59

Thank you, I can envision the setup. I have a small lathe and arthritis in my hands, this technique could help me a lot. Thanks!

9 July 2024, 11:58

Regarding weld's l have seen super glue used through a fine tip, you need steady hand n move in pattern to create weld.

Sorry l was looking at the resin 🤔🤣.

Good stuff be keeping eye

On progress 👍👍

9 July 2024, 13:30

@Ben M: What also works is a modeller's vice. Clamp the wheel in that, scrape down the seam with a straight knife over a third or so of the wheel, then unclamp and turn it, and repeat. If I scrape more than about two or three wheels by hand, my fingers ache enough that I have to stop, so the vice helps a lot. But you also get a lot of plastic scrapings all over your modelling area, so this time, I figured I'd put those in someone else's hobby room instead for a change 😉

@Mr D: Hahaha! The ones on the resin were put there by Resicast 🙂 But I'll now have to make ones that look similar, or at least not out of place next to them. I'm thinking a thin string of two-part epoxy, textured with a sharp tool.

9 July 2024, 17:09

Good video 👍, the finish on the flat plate work looks authentic, l think it's had better rough cast look from the brush stippling before he added the putty coat.

Good idea on the weld , epoxy putty best as regular epoxy levels out again.

11 July 2024, 12:55

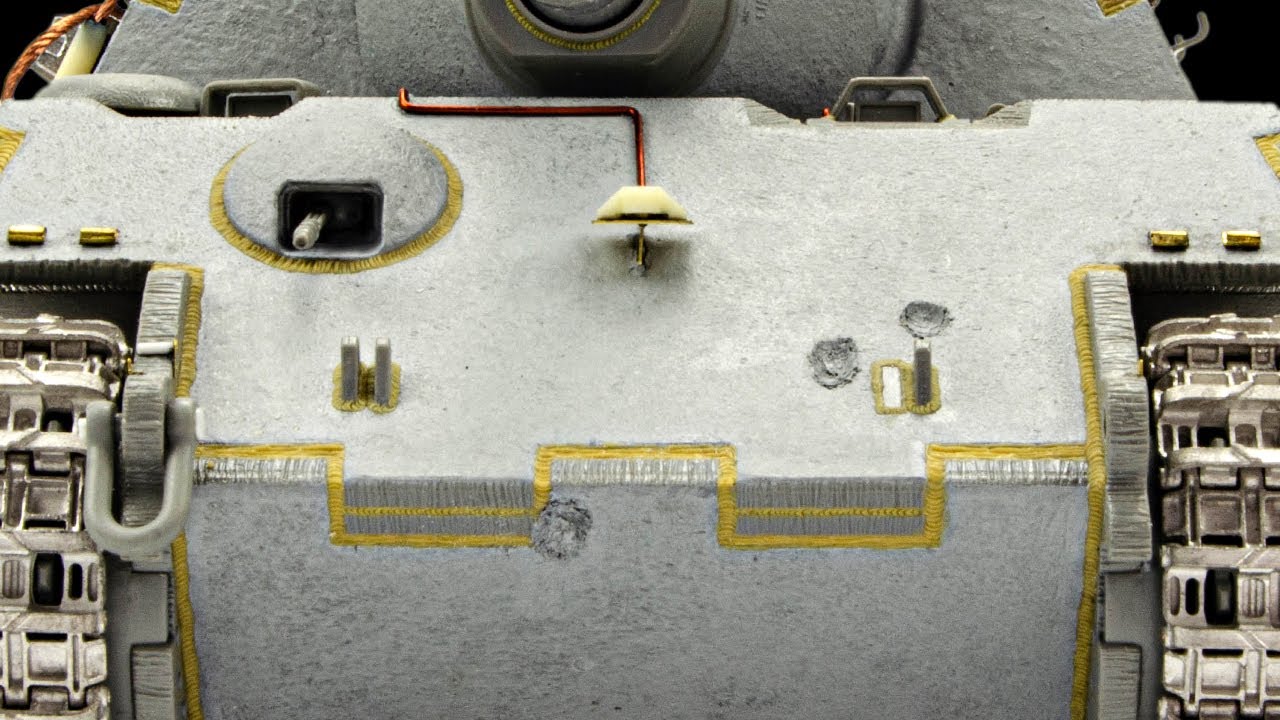

I've begun to add the weld seams now — see photo 23 🙂 Basically, Magic Sculp two-part epoxy putty that I mixed up a very small amount of, then took even smaller amounts from that and rolled it as thin as I could in my hand before pressing it into the join between the parts. Getting it to stick there is tricky, especially once I began texturing it with the tip of a knife — it wants to adhere to skin and steel much better than to plastic, unfortunately 🙁 But with a bit of perseverance it does eventually stick.

11 July 2024, 17:41

I see some heavy duty equipment here and a lot of elbow grease... Good job so far, Jakko! Keep it up!

16 July 2024, 15:17

Thanks, though this is fairly straightforward. The most difficult part was finding a good way to curve the splash plates, really.

16 July 2024, 17:21

Taking shape now, the green welding joints are looking a better medium.

Interesting to see an adaptation taking place of the original.

Thanks for your posts, good to see steps

👍👍👍

25 July 2024, 21:06

Thanks. TBH, I don't really care to look at photos of finished models — I much prefer seeing how they got to be that way, after which the finished pics make sense 🙂 So I post in-progress photos instead of only what it looks like at the end.

26 July 2024, 08:57

Looks great, what an interesting subject. I enjoy your in progress photos.

My favorite bit is the martini glass holder up there on the bridge.

30 September 2024, 16:06

Hi Jakko👋

Very nice... great job, thanks for the uploads....be interesting to watch progress.

Like it 😁👍👍

30 September 2024, 16:20

Thanks, guys 🙂

> I enjoy your in progress photos.

Speaking for myself, I much prefer looking at how a model was built, than how it looks when it's finished 🙂

> My favorite bit is the martini glass holder up there on the bridge.

I take it you mean the No. 19 set 'B' aerial …

30 September 2024, 17:08

Wow, that took a lot of work. Great result, and such an interesting vehicle. I wonder how many of these conversion kits actually get built!

18 October 2024, 12:41

Brilliant 👌 Well done a nice custom model 👍👍

All the work paid off now 👍👍

18 October 2024, 16:28

Thanks 🙂 It did take a good while, but I'm pretty happy with how it came out. And I agree with Ben, you have to wonder how many people actually build extensive resin conversion kits these days … they're definitely not for the modeller who just wants to put the parts together.

FWIW, I also have Resicast's Sherman V DD and Terrapin (both complete kits) in my stash, which will probably be even more work 🙂

18 October 2024, 17:07

I've looked at an m33 conversion for an m3 along with a resin gun to go behind it but honestly builds like this convince me to save my money; I'm not likely to ever build it and it'd just sit in my stash. I like to spend money on things I'll actually build.

I can just vicariously enjoy builds like this! I also really enjoyed your CDL build, all the corrections you did to it were really amazing. I like how deeply you research these things.

18 October 2024, 20:05

Yes, an M33 would be a pretty intensive build, I would imagine 🙂 TBH, Resicast is probably one of the better "traditional" conversion-kit brands you could go for, but if you can't actually see yourself starting it at all then I agree it's just better to leave it. The main reason I had the BARV kit (and the Terrapin, DD, and some others) is because Resicast was going to close last year, and I don't see any plastic kits of any of these coming out in my lifetime …

As for research: I just want to build a model that's fairly accurate, and when the manufacturer gets it clearly wrong, I try and correct the kit 🙂 That's basically what lead to the detailling added to this model, but also the CDL modifications, adding a FULL set of deep-wading gear to a Churchill, etc. I couldn't have done any of these without being able to ask other people online about things I couldn't discover or work out on my own, though.

18 October 2024, 20:33

Album info

The Resicast conversion set to make a Sherman Beach Armoured Recovery Vehicle out of the Asuka Sherman III kit.