Work in Progress: Sopwith Camel Comic

As expected from my other Camel build perfect fits!

From two plastic parts? Probably not.

Could be used ...

Quote from the foreword of the "Info Eduard" journal from February 2022 (on the Eduard homepage as PDF):

"Also interesting is the high number of 723 sold Camel seats. Although, in this case, it is necessary to add that this is a little gem of a piece, looking like it came out of a fairytale workshop with liberal sprinklings of fairy dust."

Exactly! And I've already bought 10 of the 723 because you can use them for many of the British planes. The first one is in my first Camel, the second in the recently introduced DH-2 and now this is the third. This is the part in question, the little black seat on the penny.

The price is fair, and colour printed belts from the thin STEEL series are also included here.

I guess the seat can stay like this?

I had the LeRhone 9J from Small Stuff in stock, so built this one first. The usual procedure ...

And I used a polarization filter on the lens for the engine pictures because of the oil wash and metal impression.

Primed white, linen paint, wood base acrylic, wood grain acrylic, MRP Clear Yellow and Clear Orange, Alclad Aluminium.

The front part is only clipped in.

Hence the decision for the normal part. First, with the help of oil paints, an imitation of wood was applied.

As indicated on the etched parts, I added the wiring from lead wire and annealed brass, and the oil pulsator got a head from drawn clear cast branch (I had removed the grey part at the very beginning).

Unfortunately the scales of the decals are not as sharp as those of the etched parts.

The struts are beautifully original, only 0.7mm thick!

After a white primer, I masked off the ribs ...

Here is the fuselage cover. The tanks in front of the cockpit on the Comic need filler caps. With a little paint it would be nice, but how should the mechanic get them open?

Here are a few tubes (0.5/0.6/0.8mm) impaled on drills and clamped.

Let's see if I can wrap some "grip" around it.

Since I had shortened the instrument panel at the bottom, you can now see unusually far, so I decided to add the tank, here painted aluminium.

.

.

.

Therefore!

I can be accused of anything, but in no case that carrier film would be visible here.

I don't know if the decals are all like this, or only here at WWI: there is also a certain variation in the print, which absolutely fits here.

I think the Camel is very successful: note how nicely the covering fabric sits over the frame of the fuselage!

The right T is 0.6mm brass tube at the top with 0.5mm brass wire soldered into a hole.

I painted other parts like wheels and tail unit at the same time.

After the photo, I retouched with a brush!

Please note also the notch at the end of the aluminium panel.

I had already shown that I had completely removed the carrier from the cockades. Now I noticed during the inspection windows that the decal even lay hollow over the masked window. Nevertheless, the carrier film came off without destroying the decal.

Conclusion: really stick to the recommendation and remove it after 10 hours. It seems to dry out further, which then makes removal unnecessarily difficult. Another lesson learned!

In the end it was mounted with super glue.

The two parts below are the "slider shoe". The one on the right was the first attempt; I didn't like it and so the one on the left is now the final version.

The suspension goes into the hole in the front.

For the aiming device there are PE parts in the Brassin set, but my reference photo of my specific Comic shows a different cross and a reversed mount order. I found the needed cross on spares PE.

The one with additional struts: In the middle the plastic kit part, from the Profipack PE part 6, or part33 from the 3D print.

For the one without struts (my Comic needs this): PE part 12 or part 32 from the 3D print. Cut already, top left.

I'm not a 3D expert. They may not have been cured sufficiently, taken out too early or packed too early?

The PE part is not an option, as this is flat.

It is very nice that every kit of the Camel includes this windscreen. So I could try to use the same part as a base for a foil with PE frame.

A lot of work as usual but nothing new.

A camel without humps looks strange, even if the distance between the bonnet and the wing is identical to the normal one.

The intake and the rigging spider are also visible.

3 pumps of 2 types, 3 different airscrews, and 10 different little PE mounts for 5 ways of mounting, two of each type.

The mounted and painted pump is top right of the Cent!

The next level of Eduard kits will be atoms in single arrangement, or what?

Here in finished state after painting and added hub on back side. Hard to see, but there I drilled 0.2mm holes and added nickel silver as bolts.

The wheels got a layer of flat clear coat and fixed on the axles. I forgot a turnbuckle on the undercarriage!

I don't know how to hold it for cleaning the seam and sprue gate, so I drilled 0.2mm holes and added brass wires.

I masked the sides, painted it alu (for the inside mirror) and then brass. Green and red are clear paints.

Finally I polished the front to get rid of seam and paint, sanded up to 12000.

The Holt flares have to be replaced after use.

Opmerkingen

Thanks to Eduard for providing the sample kit and the 3D printed weapon set!

It would be nice if some of you would follow my build.

You are welcome!

As the Comic was never available as injected molded kit in 1/48 (only a long gone resin conversion) this is for me the kit of the year 2022 ❤️️ 👍

If only I could decide on a marking! 🤔

Count me in Frank, looking forward to see this come together. The kit looks very nice and I am sure tjis eill turn out as nice as your first Spit from this mold.

Welcome to the show mates! With the finished Nieuport Triplane this one could enter the bench.

I'm in, as usual. Looking forward to more enjoyable learning, before getting one of those kits.

Thank you mates!

After a short holiday I'm back on the bench. The airscrew is in shape and primed. A lot was done for the interior.

you just did when you entered a comment in this build, for example. now, you will be notified when there are new comments or updates 😉

Hi Karl, not a naive question, as it's not as obvious as it could (should?) be. And just so you know, you can 'Disable Notifications ' (that is, stop following the thread) by choosing the option under the 'wheel' icon at the top of the discussion.

Next batch of pictures - with successful engine test run 😉

Now I have to take care of the fuel parts on the left, the floor with the control stick etc. and the instrument panel, then the fuselage can be closed.

Unfortunately I have not found a photo of the cockpit of the Camel Comic, so there is a lot of guesswork involved. So if you know one, please tell me!

David, good question!

I added a description to the Album, so that it is more prominent on top and is not got lost in the comments here.

Feel free to ask if something is not clear.

Another inspiring step-by-step insight into your world of fine craftsmanship, and artistic painting too 🙂

Thank you Michael and Bruce, I'm glad that you like those parts!

Now pictures of two new stories: instrument panel (here I found a bug in the kit - I'm bughunter 😉 ) and struts.

Have fun!

Bugsy (or iz that Mr. Bugsy, to you?) .....

.....your strut technique with the two pieces of wood glued over a wire and sanded down is a great idea!

However, most (if not all, but a very small number) of us mere mortals have your skill set or tool set...how hard would it be to mold those wood pieces in plastic from a kitmaker like Eduard?

They could include "regular struts", which they already do...just add these as an option...how hard is it to glue two pieces of styrene together with a wire inside....not very hard....I'm in!

Thank you for sharing this technique!

BTW...also thanks for the rigging diagram of that crazy Nieuport Triplane....Nieuport Triplane "RFC/RNAS" | Album by Lochsa_River (1:72)

Not sure if this will work. The struts are already 0.7mm thin, I don't know if it possible to mold them in half size.

I showed my struts more detailed in the DH-2 work in progress album.

And the Ni Triplane - I had to create my own "rigging diagram". Every time I checked the high res pics on Imperial War Museum web site, I found new rigging lines 😉 So with adding them all I understand slowly how it works.

Nice to see some new kits of these old birds in 1/72 lately.

Wow! The buttons and switches look like they could be used immediately 👍

Another stunning build and comprehensive build log. 👍 Count me in! 🙂

Welcome to the show and thank you!

The next batch of pictures uploaded.

Does anyone recognise the fill level of the tank? Then you know my current mood.

Have I forgotten anything? If not, the lid can actually be put on as well!

Have I ever mentioned that I love the new Eduard decals?

I can be blamed for anything, but in no case that carrier film would be visible here!

While the oil paint of the simulated wooden parts was hardening on the fuselage, I worked on the landing gear.

As with the normal Camel, I wanted to replace the very soft struts. Unfortunately the same technique again, late Camels have a modified landing gear.

For good symmetry, it is best to always build both sides at the same time.

It was a lot of work, but is now an extremely robust and original undercarriage!

Mir sind leider die Superlativen & Belobigungen ausgegangen daher gibt es heute „nur" ein 👍 🙂

Thank you mates!

Did anyone hear the punch? I hit my limit so hard, that's all I can do.

Marcin, oh yes, sometimes you are standing in your own way!

In the meantime, the oil paint had also hardened so that I could continue working on the fuselage.

Unfortunately my camera always has a hard time with some colours, despite white balance it is not as red in the original as in the pictures.

Now allow to dry thoroughly and then re-mask and paint the front in aluminium.

As always an excellent eye for the detail and great craftsmanship. A pleasure to follow 🙂

Thank you very much for your kind words Christian!

After the virus put me out of action, I'm feeling much better now. So I'm back on deck and can work full steam ahead on this little Camel (without humps) again!

Sorry to hear you caught the virus, Bughunter, but glad that you are on the mend. Enjoying seeing how you bring your creation into life 🙂

Thank you Bruce!

Marcel - you are the only mate who has been able to see this work with own eyes! Thank you very much for the visit 👍

Thx Roland, but "So much to learn!" - for me from your fantastic builds and paint jobs!

Next batch of pics added - beside some detail painting the fuselage is nearly done 🙂

Amazing work here. This is a How to do magazine. Your doing outstanding work. Thanks for sharing this.

JB

Wow! Thank you very much for such a great feedback 👍

Some new pictures added, with a lot of fasteners and some decals.

Frank, this build develops great. Again great craftsmanship. I am looking forward to the next update

The detailing (fasteners, steel cable on alu panel) is near mad, litteraly ! And great work on the intricate painting... The funny thing is that I was puzzled about what I thought was some odd and somewhat overdone weathering on the fuselage's fabric until I saw it 'moved' depending on the pictures. Then I understood it was a reflection (of your flash?) from your trademark 1-cent coin ! I should have known better 😉

Thank you mates for following and leaving comments!

Boris, all little details are also added on my first Camel last autumn. The problem is, if you have done it once I need to do this too on a comparable model. And this variant is for me "The kit of the year", so I want to do all, what is possible.

Sorry for the shadow of the Cent. I do not use flash (due to hard shadows), but the light comes from my roof window.

Thank you Guy!

The next batch of pictures uploaded, worked on different things.

Now all the struts can be finalized, especially the shape at the end, and painted.

The tail skid from the kit is only 0.5mm thin, so I don't trust the plastic to be robust enough for transport, exhibitions, etc. So a new one, like the other Camel.

Totally in awe at the gorgeous paint finishes 😃 Love how you totally play down the manufacture of the filler caps 😉

bah... with bughunter's projects, we usually reserve comment until he does something TRULY spectacular. The run of the mill amazement just doesn't cut it anymore...

Thank you very much!

Over time, some parts become "routine" after I find a way to make them reasonably. I have already installed such fuel caps on previous models.

So that colleagues like Greg are still impressed and it doesn't get boring, I try "something TRULY spectacular" every now and then. This will then become the standard for the next models, but this way I can raise the bar a little bit at a time.

Well...I was going to do some modelling this afternoon, but instead I decided to gaze in wonder at your lovely work. Certainly not time wasted. 🙂

Incidentally, could you please tell me what type of solder you use?

Thank you very much gorby!

I'm still using my "old school" electronic solder Sn60PbCu2. The 2% copper are only to increase the working time of the copper soldering tip. Sn %60 and Pb %38 have the lowest melting temperature of 183 °C, see en.wikipedia.org/wiki/Eutectic_system

But I must admit, that I'm doing a other project of a french monoplane in parallel, with a lot of scratch work. Don't miss it! Full scratched cockpit from wood and metal | Album by bughunter (1:48)

Thanks for that Frank.

(I thought I'd thanked you yesterday but obviously I must be madder than even I thought.) 😄

Michael, I find the german Wikipage a bit better: de.wikipedia.org/wiki/Eutektikum

The fascinating fact is that the melting point at exactly this mixing ratio is much lower than for both metals in pure form.

Yes. I have been flabbergasted by this fact - which was new to me - too.

Now that other projects have crossed the finish line, I would like to resume my work on this project. Stay tuned!

After finishing some other projects I continued on this Camel without humps (is that still a Camel? 😉 ) and some problematic things are solved. Looks not bad for a successful end this time.

Living in Frankonia (an area in nothern Bavaria) this is about the highest praise you might ever get on your life. 😉😂

You are two funny guys 👍 Thanks!

I was out of the town for Easter holiday including some days more for hiking, but now I'm back and will continue to work on this one soon.

Some more details are added and more parts mounted so we come closer to the finish.

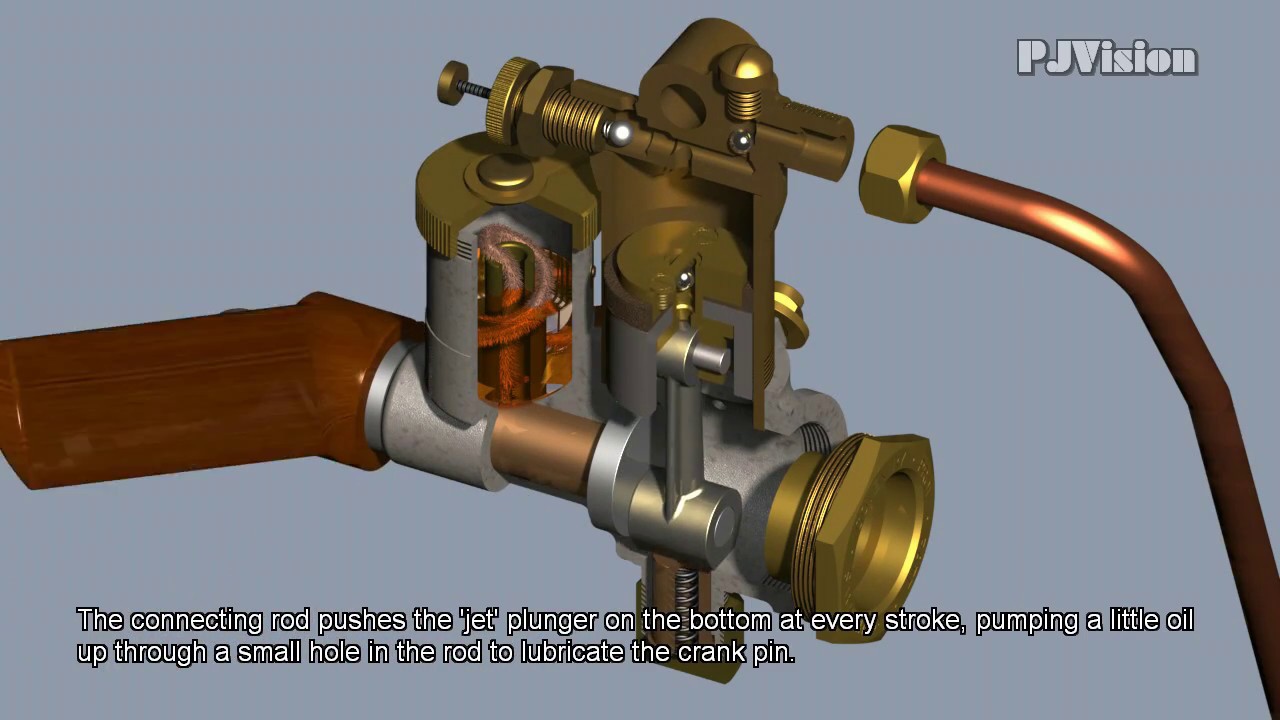

I added again this most impressive Rotherham Air Pump by Eduard to the project and the model. I think that are the actual technology (and modeler like me handling) limits. The next level would be atoms in single arrangement, or what?

For comparison (pic 145) here is a ref pic by James Fahey of a Rotherham Air Pump on a Camel flying today, here mounted on a upper strut.

[img1]

Not sure what else could be added to your rendition of the pump. Simply amazing!

Thank you Alec! We have to say thank you Eduard for producing such nice accessories.

After I have seen some pictures (typically in museums) I was no more sure about the wingnuts on the cowling, as the wingnuts are going into the fuselage on that pics.

But beside my references of a flying Camel I found a high res pic on Wikipedia: The wingnuts are on the cowling side! That pic is huge.

[img1]

An incredible piece of modelling art, coupled with the highest level of expertise! This is simply great! It's hard to believe how beautifully you build!

Thank you Pietro and Roland!

Roland, I hope you have the chance to see my new flood of models this year in Ried (and your booth is not empty again as last time). My plan is to finish one model a month, we have middle of April and this number 4 is on a good way to the finish 😉

I can't keep looking at your posts, my eyes are so sore from the all the dazzling skills!!

I usually need to lie down for a bit after as well. Frank's projects have that dizzying effect on people. 🙂

The air pump is even more remarkable than your usual remarkable work Frank.

aaah, here comes that family-pizza-sized 1-cent coin again!!! 😉 😉 👍

Nice to read you funny comments mates 👍 Thx!

@Andy and Greg - Believe me, I don't want to hurt anyone, not even myself (with sharp tools at the workbench).

@gorby The great thing about such nice accessories like the Rotherham Air Pump is, that Eduard sell it for the Camel, but you can use it in a more generic way. My first kit is empty because I equipped both Camels and the recent F.K.8 with such pumps, but I have more of this gem in my stash.

@Slavo I swear that the cent is real! The fake was in the pictures for a short time during the last project 😉

I will now edit pictures for another update.

By far not ready, but some steps closer to the finish line.

Missing: Rudder (just removed decal) with control wires, tail rigging with 16 terminals, undercarriage rigging, Lewis MGs, detail painting, metalize rigging wires, weathering, may be night fighter equipment like lamps and Holt flares (kit provided) and may be more.

There is such a thing as a "Rotherham Air Pump"? The folks of the South Yorkshire former steel town will be in awe 🫢 I wonder if there is a "Doncaster water injector" too!….

Thx mates!

Andy, your water injector is may be used in WWII (for increase power of engines) but your question invited my to google for "Rotherham Air Pump" and beside nice pictures I found this interesting video: Youtube Video

Aahhh! It was form Coventry – my home town. Remarkable what we used to produce – with the emphasis on 'used to'. 🙁

A lot of good things came out of Cov (and the usually stayed out). 😄

Although this is standard with your builds, again I admire your craftsmanship. I have followed the entire build from the beginning and again admire your craftsmanship and precision.

Thank you very much mates!

Thanks also Simon for commenting and following. There are many who follow but never leave anything. Very rude of these stalkers.

I think there will be a new interesting update tomorrow.

Thank you CaptGPF, yes a lot of details, but a downscaled original needs that 😉

Now WWW - Weapons, Weathering and some nice Weather for the final outdoor pictures are needed!

Thank you Ludvík, also for the likes!

This Camel without humps is now finished and the weather forecast for tomorrow sounds good for the final outdoor pictures.

By the way, for those who now also want to build this Camel: the Profipack is currently available with a 50% discount as part of the SWEEP campaign: eduard.com/eduard/so..amel-comic-1-48.html

So, this project has reached its final state! Please jump over to the album with the final pictures:

Sopwith Camel Comic B4614 | Album by bughunter (1:48)

Thanks for watching and all your interaction during the build!

Album info

The Camel Comic is a night fighter version of the Sopwith Camel.

A few words about this variant: Why conversion to a night fighter?

It soon became apparent that the muzzle flash of the Vickers MG in the normal mounting position blinded the pilot in the dark. Therefore, it was decided to use two Lewis MG on the wing, similar to the SE.5a (for the Lewis MGs exists also incendiary ammunition, which was more successful against airships).

However, the pilot has to pull them down on rails to change the drums, and this was not possible with the Camel, as the cockpit was too far forward. Therefore the tank (which is behind the pilot in the normal Camel) and cockpit were exchanged. This eliminated the hump of the Vickers MG, the cockpit opening further back than normal. In short: this is an almost new model.

About the name:

First the Sopwith 1 1/2 Strutter was used as a night fighter with weak armament. Pilots used to more heavily armed fighters found the Strutter "a joke of a fighter", so the name Comic came into being and was then retained for the Camel night fighter.

That is the first time we see this version in 1:48 as injection molding.

If you check the sprues carefully, we can also expect a ships Camel, with has some other modifications.